How to Clean and Maintain Integrated Heating and Cooling Equipment?

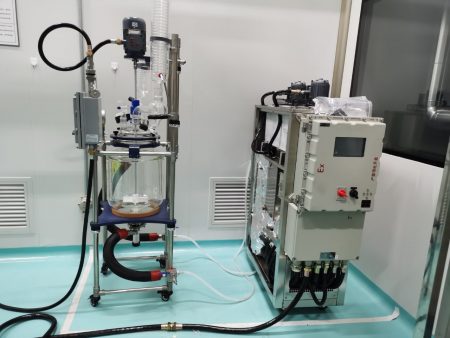

The heating and cooling integrated equipment is used in the pharmaceutical, chemical, and laboratory industries to connect reactors for refrigeration and heating reactions. It is suitable for endothermic and exothermic process control during the reaction process. It can linearly control the temperature of materials in the kettle, and the program can be selected. In the control mode, the temperature difference between the heat transfer medium and the material can also be set. The whole heating and cooling integrated equipment adopts a fully closed circulation system, which will not generate oil mist at high temperature and will not absorb moisture at low temperature. There is an expansion tank in the system. During the process, the heat transfer medium expands with heat and contracts with cold.

How to clean and maintain the heating and cooling integrated equipment?

1. Clean the surface of the equipment: When the surface of the equipment is dirty, use a soft cloth with neutral detergent or soap to clean the equipment. Be careful not to use petroleum, acidic solvents, abrasive powder, steel brushes and sandpaper, so as not to damage the plastic sprayed surface.

2. Check before use: After long-term use, please check whether the heat exchanger of the circulation device is blocked by dust or dirt. If necessary, clean the surface with dry compressed air, a vacuum cleaner or a soft brush.

In order to ensure the safety and effectiveness of cleaning the heating and cooling integrated equipment, it must be operated under the condition of power failure, and secondly, it must be ensured that it is stopped for one hour before operation. Clean every part of the oil cooler in place. Of course, in principle, cleaning the surface of the circulation unit does not damage the product. Cleaning the oil tank is the core equipment of the oil cooler, and the excess oil inside must be drained before cleaning.

When cleaning, the user must clean the bottom of the tank. In order to ensure the cooling effect, the cooling coil of the circulation device also needs to be cleaned regularly. During the cleaning process, the cleaning of the air filter cannot be ignored, so as not to shorten the service life of the filter.

It is worth noting that the filter of the heating and cooling integrated device is not easy to clean, so please try to remove it for cleaning. If the dirt is serious, you can clean the filter with warm water and a neutral detergent not exceeding 40°C. Get better results. Check and clean the oil suction filter regularly according to the cleanliness of the oil to prevent dust from clogging.

We are a professional manufacturer of temperature control equipment, supporting customized services, please consult us for details!

Temperature Control Range: -45°C ~ +250°C 7 Inch Color Touch Screen With 2pcs of LED Display Controller Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -25°C ~ +200°C 7 Inch Color Touch Screen With 2pcs of LED Display Controller Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -40°C ~ +200 °C Temperature Control Accuracy: ±0.5 °C 7-Inch,10 Inch color FTF Touch Screen Display Note: Both Air Coo...

Temperature Control Range: -10℃ ~ +150℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -25℃ ~ +200℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -25℃ ~ +300℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -45℃ ~ +250℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -45℃ ~ +300℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -60℃ ~ +250℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -60℃ ~ +300℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -70℃ ~ +250℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -80℃ ~ +250℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -90℃ ~ +250℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -100℃ ~ +100℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled A...

Temperature Control Range: -25°C ~ +200°C One Machine for Two Reactors Temperature Control Accuracy: ±0.5 °C 7-Inch,10 Inch color FTF Touch Screen...

Temperature Control Range: -40°C ~ +200°C One Machine for Two Reactors Temperature Control Accuracy: ±0.5 °C 7-Inch,10 Inch color FTF Touch Screen...

Temperature Control Range: -25°C ~ -5°C (optional: -150°C ~ -5°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Semi-Closed (Bipolar)...

Temperature Control Range: -45°C ~ -10°C (optional: -150°C ~ -5°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Semi-Closed (Bipolar...

Temperature Control Range: -18°C ~ +30°C Microcomputer Temperature Controller High Performance Circulating Pump Note: Both Air Cooled And Water C...

Temperature Control Range: +5°C ~ +35°C Microcomputer Temperature Controller High Performance Circulating Pump Note: Both Air Cooled And Water Co...

Temperature Control Range: -60°C ~ -10°C (optional: -150°C ~ -5°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Semi-Closed (Bipolar...

Temperature Control Range: -80°C ~ -30°C (optional: -150°C ~ -5°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Semi-Closed (Bipolar...

Temperature Control Range: -110°C ~ -50°C (optional: -150°C ~ -5°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Semi-Closed (Bipola...

Temperature Control Range: -150°C ~ -110°C Siemens PLC Controller, Danfoss Electronic Expansion Valve Semi-Closed (Bipolar) Piston Compressor, Sem...

Temperature Control Range: -25°C ~ +30°C (optional: -120°C ~ +35°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Brand Compressor, C...

Temperature Control Range: -45°C ~ +30°C (optional: -120°C ~ +35°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Brand Compressor, C...

Temperature Control Range: -60°C ~ -20°C (optional: -120°C ~ +30°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Brand Compressor, C...

Temperature Control Range: -80°C ~ -20°C (optional: -120°C ~ +30°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Brand Compressor, C...

Temperature Control Range: -120°C ~ -70°C (optional: -120°C ~ +30°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Brand Compressor, ...

The temperature range of the equipment is -110 ℃ ~ -40 ℃, using environmentally friendly refrigerant, the cooling speed is fast. The products use b...

It is widely used in high and low temperature testing of semiconductor equipment. Cold and heat sources for high temperature and low temperature co...

Temperature Control Range: -115°C ~ +225°C Siemens PLC Controller Danfoss / Emerson Fittings Application: Laboratory, Research Institute, ...

Automobile Test Chillers

Temperature Control Range: -40°C to +100°C

View Products

Semiconductor Test Chillers

Temperature Control Range: -85°C to +250°C

View Products

Industrial Refrigerators

Temperature Control Range: -150°C to -10°C

View Products

Copyright information belongs to lneya-online.com, please contact email for details: lilia@lneya.com

Or scan the WhatsApp or WeChat QR code below to contact us.

WhatsAPP WeChat

LNEYA

LNEYA

简体中文

简体中文