Battery Energy Storage System Cooling Solutions: Liquid Cooling VS Air Cooling

Battery Energy Storage System Cooling Chiller is a device used in battery thermal management. Common cooling methods in battery thermal management include air cooling and liquid cooling. So, do you know the difference between these two cooling methods?

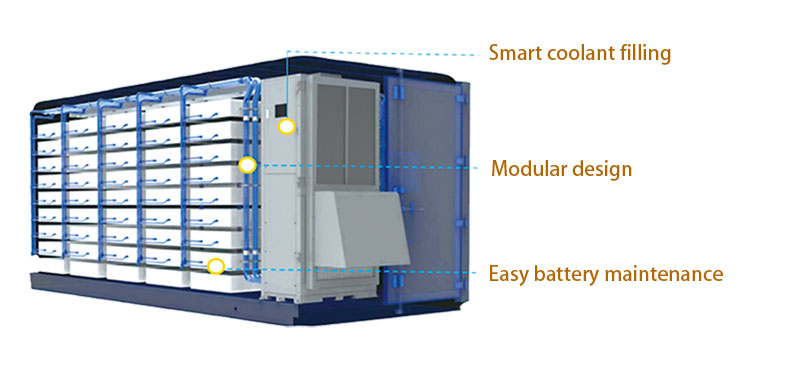

There are two thermal management methods for lithium battery units, air cooling and liquid cooling have their own characteristics. Battery Energy Storage System Cooling Chiller can be highly integrated with the battery pack, easy to install on site, occupies a small area, and there is no need to worry about dust, water vapor condensation and other issues. In the case of thermal runaway precursors, the liquid cooling solution can rely on a large flow of cooling medium to force the battery pack to dissipate heat and realize heat redistribution between battery modules, which can quickly avoid the continuous deterioration of thermal runaway and reduce the risk of runaway. The air cooling system has the characteristics of simple system, low manufacturing cost, and easy installation. It is widely used in scenarios where the battery energy density is low and the charging and discharging speed is slow.

1. Under the same inlet temperature and harsh wind speed and flow rate, the temperature of the liquid-cooled battery pack should be 30-40°C, while the temperature of the air-cooled battery pack should be 37-45°C. Liquid-cooled Battery Energy Storage System has better temperature uniformity.

2. In order to achieve the same average battery temperature, air cooling requires several times higher energy consumption than liquid cooling. Under the same power consumption, the temperature of the battery pack is higher for air cooling than for liquid cooling. Liquid cooling consumes less power.

3. Due to factors such as air specific heat capacity and small convective heat transfer coefficient, the heat transfer efficiency of battery air cooling technology is low, and the heat generated by the battery increases, which will lead to excessively high battery temperature and the risk of thermal runaway; the liquid cooling system can greatly reduce the thermal runaway of the battery risk.

4. The liquid cooling system is easier to ensure that the battery works at a comfortable temperature. Compared with the air cooling system, the battery life will be extended, and the investment in liquid cooling is less in terms of the overall life cycle.

The air cooling system has the advantages of small initial investment, low maintenance cost, and easy maintenance. It is more suitable for small civilian or commercial battery thermal management. However, Battery Energy Storage System Cooling Chiller has gradually become a suitable battery cooling method in large-capacity and high-energy-ratio fields such as large ground power stations.

| Air Cooling VS. Liquid Cooling | ||

| Air Cooling | Arrefecimento líquido | |

| heat exchange medium | Air | Liquid |

| drive parts | fan | no fan required |

| heat dissipation | General | The specific heat capacity of the coolant is 1000 times that of air, and the heat dissipation capacity is much higher than that of air cooling |

| energy saving | PUE is within 2.2 | PUE is within 1.2 |

| noise | high noise | low noise due to no fan |

| construction cost | The low-density layout of the cabinets takes up a large area of the equipment room, requiring the use of traditional precision air conditioners and cold and hot pipeline designs. | The high-density layout of the cabinet reduces the occupied area, and the low PUE means that the power supply, power distribution and infrastructure scale facilities are reduced. |

| site selection | It has high requirements on environmental climate and power factors. | It is not affected by the environment and climate, and is not restricted by energy policies, so it can be deployed anywhere. |

Produtos e soluções

| Modelo | CNYL -45 |

| Capacidade de arrefecimento | 45KW |

| Precisão do controlo da temperatura | ±0,5℃ Registo de temperatura em tempo real |

| Refrigerante secundário | Anticongelante de etilenoglicol, conceção totalmente fechada do sistema de circulação do refrigerante |

| Refrigerante | R410A |

| Fluxo | 300L/min~400L/min Definir histórico de visualização |

| Baixa pressão eléctrica | Schneider/Siemens |

| Ecrã de visualização | Ecrã tátil a cores de 7 polegadas |

| Potência | 380V 50HZ Escolha 220V60HZ 460V 60HZ |

| Material da casca | Pulverização de chapa laminada a frio REL7035 |

| Tubagem interna | SUS304 |

| Modelo | CNYL-5 | CNYL-8.5 |

| Capacidade de arrefecimento | 5KW | 8,5KW |

| Exatidão | ±0,5℃ Registo de temperatura em tempo real | ±0,5℃ Registo de temperatura em tempo real |

| Temperatura mínima de entrada da água | 15℃(Pode ser personalizado de acordo com o sistema de bateria) | 13℃(Pode ser personalizado de acordo com o sistema de bateria) |

| Deteção do sensor de pressão do sistema | Pressão de saída do líquido, pressão de entrada do líquido, pressão alta e baixa do sistema de refrigeração | |

| COP | *2.0 | *2.2 |

| Compressor | Compressor hermético (1 conjunto) | 34cm3 /revCompressor scroll totalmente fechado (1 conjunto) |

| Refrigerante | R410A | R410A |

| Ecrã | Ecrã tátil a cores de 7 polegadas | Ecrã tátil a cores de 7 polegadas |

| Gama de temperatura ambiente de funcionamento | -45℃~55℃ | |

| Gama de tensão de controlo | 18-32V | 18-32V |

| Potência máxima de refrigeração de alta pressão | 2.2KW | 3,5KW |

| Potência eléctrica média de entrada do sistema de refrigeração (kW) | +1,5kwfrequência ajustável | +2kwfrequência ajustável |

| COP | *2.0 | *2.2 |

| Modelo | CHDYL-4 |

| Capacidade de arrefecimento | 4KW |

| Exatidão | ±1℃ Registo da temperatura em tempo real |

| Compressor | Compressor hermético (1 conjunto) |

| Refrigerante | R134A |

| Ecrã | Ecrã tátil a cores de 7 polegadas |

| Sistema de controlo | PLC |

| Comunicação | CAN |

| Gama de temperatura ambiente de funcionamento | -45℃~55℃ |

Fornecemos a conceção e o fabrico de sistemas completos de controlo de temperatura. Desde modelos padrão até produtos personalizados completos até 1000 toneladas. Somos especializados no serviço ao cliente e dedicamo-nos a ajudar cada cliente a ter o sistema de controlo de temperatura ideal para as suas necessidades específicas.

Fornecemos soluções personalizadas não padronizadas.

Correio eletrónico: info@lneya.com ID WeChat: +8615251628237 WhatsApp: +86 17851209193

LNEYA

LNEYA

简体中文

简体中文