Battery Energy Storage System Cooling Solutions: Liquid Cooling VS Air Cooling

Battery Energy Storage System Cooling Chiller is a device used in battery thermal management. Common cooling methods in battery thermal management include air cooling and liquid cooling. So, do you know the difference between these two cooling methods?

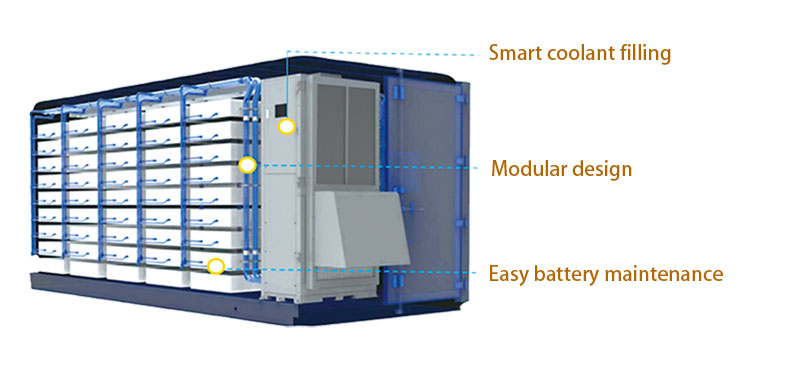

There are two thermal management methods for lithium battery units, air cooling and liquid cooling have their own characteristics. Battery Energy Storage System Cooling Chiller can be highly integrated with the battery pack, easy to install on site, occupies a small area, and there is no need to worry about dust, water vapor condensation and other issues. In the case of thermal runaway precursors, the liquid cooling solution can rely on a large flow of cooling medium to force the battery pack to dissipate heat and realize heat redistribution between battery modules, which can quickly avoid the continuous deterioration of thermal runaway and reduce the risk of runaway. The air cooling system has the characteristics of simple system, low manufacturing cost, and easy installation. It is widely used in scenarios where the battery energy density is low and the charging and discharging speed is slow.

1. Under the same inlet temperature and harsh wind speed and flow rate, the temperature of the liquid-cooled battery pack should be 30-40°C, while the temperature of the air-cooled battery pack should be 37-45°C. Liquid-cooled Battery Energy Storage System has better temperature uniformity.

2. In order to achieve the same average battery temperature, air cooling requires several times higher energy consumption than liquid cooling. Under the same power consumption, the temperature of the battery pack is higher for air cooling than for liquid cooling. Liquid cooling consumes less power.

3. Due to factors such as air specific heat capacity and small convective heat transfer coefficient, the heat transfer efficiency of battery air cooling technology is low, and the heat generated by the battery increases, which will lead to excessively high battery temperature and the risk of thermal runaway; the liquid cooling system can greatly reduce the thermal runaway of the battery risk.

4. The liquid cooling system is easier to ensure that the battery works at a comfortable temperature. Compared with the air cooling system, the battery life will be extended, and the investment in liquid cooling is less in terms of the overall life cycle.

The air cooling system has the advantages of small initial investment, low maintenance cost, and easy maintenance. It is more suitable for small civilian or commercial battery thermal management. However, Battery Energy Storage System Cooling Chiller has gradually become a suitable battery cooling method in large-capacity and high-energy-ratio fields such as large ground power stations.

| Air Cooling VS. Liquid Cooling | ||

| Air Cooling | Flüssigkeitskühlung | |

| heat exchange medium | Air | Liquid |

| drive parts | fan | no fan required |

| heat dissipation | General | The specific heat capacity of the coolant is 1000 times that of air, and the heat dissipation capacity is much higher than that of air cooling |

| energy saving | PUE is within 2.2 | PUE is within 1.2 |

| noise | high noise | low noise due to no fan |

| construction cost | The low-density layout of the cabinets takes up a large area of the equipment room, requiring the use of traditional precision air conditioners and cold and hot pipeline designs. | The high-density layout of the cabinet reduces the occupied area, and the low PUE means that the power supply, power distribution and infrastructure scale facilities are reduced. |

| site selection | It has high requirements on environmental climate and power factors. | It is not affected by the environment and climate, and is not restricted by energy policies, so it can be deployed anywhere. |

Produkte und Lösungen

| Modell | CNYL -45 |

| Kühlleistung | 45KW |

| Genauigkeit der Temperaturregelung | ±0,5℃ Temperaturaufzeichnung in Echtzeit |

| Sekundäres Kältemittel | Ethylenglykol-Frostschutzmittel, vollständig geschlossene Bauweise des Kältemittelkreislaufs |

| Kältemittel | R410A |

| Durchfluss | 300L/min~400L/min Anzeigeverlauf einstellen |

| Niederdruck elektrisch | Schneider/Siemens |

| Bildschirm | 7-Zoll-Farb-Touchscreen |

| Strom | 380V 50HZ Wählen Sie 220V60HZ 460V 60HZ |

| Material der Schale | Kaltgewalztes Spritzblech REL7035 |

| Interne Verrohrung | SUS304 |

| Modell | CNYL-5 | CNYL-8.5 |

| Kühlleistung | 5KW | 8,5KW |

| Genauigkeit | ±0,5℃ Temperaturaufzeichnung in Echtzeit | ±0,5℃ Temperaturaufzeichnung in Echtzeit |

| Minimale Wassereintrittstemperatur | 15℃(Kann je nach Batteriesystem angepasst werden) | 13℃(Kann je nach Batteriesystem angepasst werden) |

| Erkennung des Systemdrucksensors | Flüssigkeitsausgangsdruck, Flüssigkeitseintrittsdruck, Hoch- und Niederdruck des Kühlsystems | |

| COP | *2.0 | *2.2 |

| Kompressor | Hermetischer Kompressor (1 Satz) | 34cm3 /UmdrehungVollständig gekapselter Scrollverdichter (1 Satz) |

| Kältemittel | R410A | R410A |

| Anzeige | 7-Zoll-Farb-Touchscreen | 7-Zoll-Farb-Touchscreen |

| Betriebstemperaturbereich der Umgebung | -45℃~55℃ | |

| Steuerspannungsbereich | 18-32V | 18-32V |

| Kältetechnik Hochdruck Höchstleistung | 2.2KW | 3,5KW |

| Durchschnittliche elektrische Eingangsleistung der Kühlung (kW) | +1,5 kWEinstellbare Frequenz | +2kWeinstellbare Frequenz |

| COP | *2.0 | *2.2 |

| Modell | CHDYL-4 |

| Kühlleistung | 4KW |

| Genauigkeit | ±1℃ Temperaturaufzeichnung in Echtzeit |

| Kompressor | Hermetischer Kompressor (1 Satz) |

| Kältemittel | R134A |

| Anzeige | 7-Zoll-Farb-Touchscreen |

| Kontrollsystem | PLC |

| Kommunikation | CAN |

| Betriebstemperaturbereich der Umgebung | -45℃~55℃ |

Wir bieten die Entwicklung und Herstellung kompletter Temperaturkontrollsysteme an. Von Standardmodellen bis zu kompletten kundenspezifischen Produkten bis hin zu 1000 Tonnen. Wir haben uns auf den Kundenservice spezialisiert und sind bestrebt, jedem Kunden zu helfen, das optimale Temperaturkontrollsystem für seinen spezifischen Bedarf zu finden.

Wir bieten maßgeschneiderte Lösungen, die nicht dem Standard entsprechen.

E-Mail: info@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

LNEYA

LNEYA

简体中文

简体中文