Data Center Chilled Water System

Driven by developments in artificial intelligence, edge computing and the Internet of Things, modular data centers have become a critical component of successful operations for many businesses. The increasing reliance on computing makes the limitations of traditional modular data centers even more apparent. These disadvantages include a lack of flexibility, inefficiencies due to scale, and high costs associated with local transaction work.

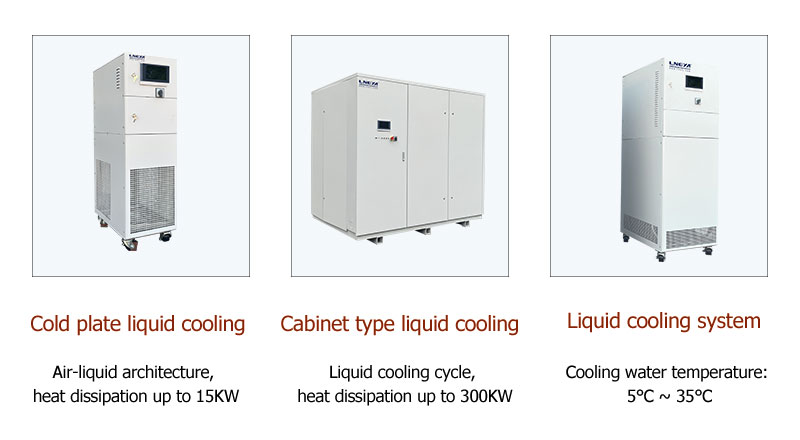

Demands for more critical power, flexible cooling options and just-in-time IT capacity are also changing. Today, traditional data centers with 60-100kW and 10-12 racks may no longer be sufficient, highlighting the importance and relevance of modular data centers that can meet the dynamic needs of today’s enterprises. Amid these challenges, businesses may consider prefabricated modular solutions (PFM) and chilled water systems as more suitable options.

Use chilled water systems to accommodate high-density computing

Thermal management is an important pillar of successful data center operations. Effective thermal management not only ensures equipment reliability but also addresses issues such as cost control, operational savings and environmental sustainability.

In the past, thermal management in data centers has been dominated by direct expansion (DX) cooling units, also known as computer room air conditioners or CRAC units. These devices remove heat from the air through a vapor compression cycle. However, the market is now looking for alternative solutions that improve operational efficiency and energy efficiency, such as chilled water systems.

Chilled water systems use water instead of air for cooling. These solutions are also based on vapor compression, but often include free cooling capabilities and achieve greater overall efficiency through a wider range of centralized components outside of the white space.

In chilled water systems, refrigerant is stored in refrigeration units with pretested circuits to prevent leaks. Monitoring systems can detect leaks during operation and help prevent refrigerant loss. Chilled water systems can use other refrigerants with less impact on the atmosphere, including hydrofluoroolefins (HFO) and HFO blends.

Advantages of Chilled Water Systems

Chilled water systems offer several combined benefits, and this solution will become the dominant global cooling technology for data centers for the foreseeable future. These advantages include its inherent large-scale efficiency, the ability to take advantage of lower ambient air temperatures for free cooling, and reduced environmental impact through environmentally friendly refrigerants. These features enhance operational capabilities and align with global sustainability goals, making chilled water systems a strategic choice for future-proof data center operations.

1. Reduce carbon emissions

Chilled water systems can use low global warming potential (GWP) refrigerant types such as HFO to reduce direct emissions. To illustrate the environmental benefits of these refrigerants, let’s look at their impact on two common chillers:

Small and medium-sized data center chillers have traditionally used R410A (GWP1924), and alternatives such as natural refrigerants such as R454B (GWP466), R32 (GWP677) or R290 are now available.

Medium and large data centers have historically used chillers with screw, or centrifugal compressors to cool their equipment, using R134a coolant with a GWP of 1300. Now, they are switching to coolants such as R513A, which has a GWP of 573, or R1234ze, which has a GWP of less than 1, to reduce their environmental impact.

Chilled water systems therefore offer a more efficient alternative to traditional cooling methods and reduce direct emissions without requiring significant investments or changes to existing data center layouts.

Chilled water systems can also reduce indirect emissions by improving energy efficiency, potentially supporting partial power usage effectiveness (pPUE) below 1.1. With growing concerns about global warming and environmental sustainability, some regions are now mandating such thermal solutions.

2. Enhance data center security and flexibility

In addition to sustainability, the design of the system also deserves attention, especially given concerns about the flammability of modern refrigerants. Chilled water systems have the advantage of placing the cooling units outside the data center, mitigating any type of risk associated with the facility’s flammable refrigerants.

Additionally, chilled water systems offer inherent flexibility in outdoor cooling unit placement. Chilled water systems have no fixed configuration requirements and physical limitations and can be adapted to a variety of operational needs.

3. Improve continuity

What’s more, the chilled water system provides a strong continuity measure, utilizing auxiliary cold water storage tanks to enhance thermal reserves during power outages, ensuring uninterrupted cooling to maintain optimal operating conditions. With these multiple benefits, chilled water systems are a reliable and effective solution to meet the ever-changing demands of contemporary data center environments.

Chilled water systems are also available in non-raised floor designs, providing the flexibility to add liquid cooling to existing data centers. This is an emerging requirement for high-density computing needs that is gaining more and more attention over time.

4. The preferred solution for high-density support

Due to its reliability, scalability and enhanced thermal capacity, chilled water is used in a wide range of applications including telecommunications, government, energy/utilities, security, manufacturing and science. Chilled water is becoming the cooling method of choice for large-scale and high-performance computing applications.

Model One: 15 ~ 150kW

| Modell | ZLFQ-15 | ZLFQ-25 | ZLFQ-50 | ZLFQ-75 | ZLFQ-100 | ZLFQ-150 |

| Temperaturbereich | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ |

| Kühlwasser | 5℃~30℃ Einsatz eines Siemens/Honeywell-Regelventils zur Steuerung des Kühlwasserflusses | |||||

| Genauigkeit der Temperaturregelung | ±0.2℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ |

| Flusskontrolle | 10~25L/min | 25~50L/min | 40~110L/min | 70~150L/min | 150~250L/min | 200~400L/min |

| Die Durchflussregelung wird über einen Frequenzumrichter eingestellt, die Genauigkeit beträgt ±0,3 l/min. | ||||||

| Kühlleistung (MAX) | 15kW | 25kW | 50kW | 75kW | 100kW | 150kW |

| Speichervolumen | 15L | 30L | 60L | 100L | 150L | 200L |

| Sole | Wasser, Silikonöl, fluorierte Flüssigkeit, wässrige Ethylenglykol-Lösung, usw. | |||||

| Controller | PLC, Fuzzy-PID-Regelalgorithmus, mit Kaskadenregelalgorithmus | |||||

| Temperaturkontrolle | Regelung der Austrittstemperatur des Wärmeträgers, mit Kaskadenregelungsalgorithmus | |||||

| Einverständniserklärung | Ethernet-Schnittstelle TCP/IP-Protokoll | |||||

| RS485 Schnittstelle Modbus RTU Protokoll | ||||||

| Geräteinterne Temperaturrückmeldung | Ausrüstung Wärmeträgeraustrittstemperatur, Mediumeintrittstemperatur, Kühlwassertemperatur | |||||

| Tankfüllstand | Import- und Export-Drucksensor-Erkennung, Kühlwasserdruck-Erkennung | |||||

| Mittlere Rohrleitung | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 |

| Wärmetauscher | Plattenwärmetauscher, besondere Aufmerksamkeit: Verwendung von sauberem Fabrikwasser erforderlich | |||||

| Bedienfeld | Wuxi Guanya kundenspezifischer 7-Zoll-Farb-Touchscreen, TemperaturkurvenanzeigeEXCEL Datenexport | |||||

| Sicherheit | Mit Selbstdiagnosefunktion; Phasenfolge- und Phasenausfallschutz; Druckschutz, Überlastrelais, thermische Schutzeinrichtung und andere Sicherheitsschutzfunktionen. | |||||

| Größe der Eingangs- und Ausgangsschnittstelle | G3/4 | G1 | G1 | DN32 | DN40 | DN50 |

| Schnittstelle zum Kühlwasser | G3/4 | G1 | DN40 | DN50 | DN50 | DN65 |

| Kühlmethode | Wassergekühlt, die werkseitige Wassertemperatur ist um mehr als 3°C niedriger als die vom Gerät bereitgestellte Mindesttemperatur, und die Wassertemperaturschwankung ist ≤3°C | |||||

| Kühlwasserdurchfluss 7~20℃ | 2.5m³/h | 4m³/h | 8m³/h | 13m³/h | 17m³/h | 25m³/h |

| Stromzufuhr | ||||||

| 380V 50HZ | 1kW | 1,5 kW | 3kW | 4kW | 5kW | 6kW |

| Shell | Kaltgewalztes Blech Spray RAL7035 | |||||

Model Two: 200 ~ 500kW

| Modell | ZLFQ-200 | ZLFQ-250 | ZLFQ-300 | ZLFQ-400 | ZLFQ-500 |

| Temperaturbereich | +5℃~35℃ | ||||

| Temperaturgenauigkeit | ±0.5℃ | ||||

| Durchflusskontrolle | 15~30m³/h | 20~35m³/h | 25~40m³/h | 30~60m³/h | 40~70m³/h |

| Flow control is adjusted by frequency converter | |||||

| Kühlleistung(MAX) | 200kW | 250kW | 300kW | 400kW | 500kW |

| Speichervolumen | 250L | 300L | 600L | 1000L | 1200L |

| Cooling System | The plant service water exchanges heat with the brine, and the brine provides cooling capacity for the heating equipment | ||||

| Mittel | Wasser, Silikonöl, fluorierte Flüssigkeit, wässrige Ethylenglykol-Lösung, usw. | ||||

| Controller | PLC, Fuzzy-PID-Regelalgorithmus, mit Kaskadenregelalgorithmus | ||||

| Temperaturkontrolle | Heat transfer medium outlet temperature control mode式 | ||||

| Einverständniserklärung | Ethernet-Schnittstelle TCP/IP-Protokoll | ||||

| RS485 Schnittstelle Modbus RTU Protokoll | |||||

| Geräteinterne Temperaturrückmeldung | Ausrüstung Wärmeträgeraustrittstemperatur, Mediumeintrittstemperatur, Kühlwassertemperatur | ||||

| Tankfüllstand | Pressure sensor real-time monitoring | ||||

| Mittlere Rohrleitung | SUS304 | ||||

| System pressure | Using the pressure sensor to detect and display on the touch screen | ||||

| Wärmetauscher | Plattenwärmetauscher, besondere Aufmerksamkeit: Verwendung von sauberem Fabrikwasser erforderlich | ||||

| Bedienfeld | Wuxi Guanya kundenspezifischer 7-Zoll-Farb-Touchscreen, TemperaturkurvenanzeigeEXCEL Datenexport | ||||

| Sicherheit | Mit Selbstdiagnosefunktion; Phasenfolge- und Phasenausfallschutz; Druckschutz, Überlastrelais, thermische Schutzeinrichtung und andere Sicherheitsschutzfunktionen. | ||||

| Größe der Eingangs- und Ausgangsschnittstelle | DN65 | DN65 | DN65 | DN80 | DN80 |

| Schnittstelle zum Kühlwasser | DN80 | DN80 | DN100 | DN100 | DN125 |

| Kühlmethode | Wassergekühlt, die werkseitige Wassertemperatur ist um mehr als 3°C niedriger als die vom Gerät bereitgestellte Mindesttemperatur, und die Wassertemperaturschwankung ist ≤3°C | ||||

| Kühlwasserdurchfluss 7~20℃ | 34m³/h | 43m³/h | 51m³/h | 69m³/h | 86m³/h |

| Stromversorgung 380V 50HZ | 7kW | 7kW | 8kW | 9kW | 13kW |

| Shell | Kaltgewalztes Blech Spray RAL7035 | ||||

LNEYA

LNEYA

简体中文

简体中文