Temperaturkontrollgeräte TCU

Temperiergeräte TCU sind Geräte, die zur Temperaturregelung eingesetzt werden. Es wird häufig in Bereichen wie der Kunststoffverarbeitung, chemischen Reaktoren und der Halbleiterproduktion eingesetzt. Die Hauptfunktion von TCU ist die Überwachung und Regelung der Temperatur von Flüssigkeiten oder Gasen in einem bestimmten Prozess. Sie kann die Temperatur mit Hilfe von Sensoren erfassen und das Heiz- oder Kühlsystem entsprechend der eingestellten Zieltemperatur anpassen, um sicherzustellen, dass die Temperatur im Prozess immer innerhalb des eingestellten Bereichs liegt.

1. Hohe Effizienz und Energieeinsparung

Die Temperaturkontrolleinheit TCU kann die Temperatur in Echtzeit überwachen und die Leistung der Heiz- oder Kühlanlage automatisch an den tatsächlichen Bedarf anpassen.

2. Stabil und zuverlässig

Die TCU-Temperaturkontrolleinheit verwendet hochwertige Sensoren und Steuerungen, um eine genaue und stabile Temperaturkontrolle zu gewährleisten.

3. Leicht zu bedienen

Das TCU-Temperaturkontrollsystem ist mit einer benutzerfreundlichen Mensch-Maschine-Schnittstelle und einfachen Bedientasten ausgestattet, mit denen die Benutzer die Temperatur leicht einstellen und anpassen können.

4. Einfache Wartung

Die Kernkomponenten des TCU-Temperaturregelungssystems sind modular aufgebaut, um Wartung und Austausch zu erleichtern.

5. Breiter Betriebstemperaturbereich

Temperaturbereich: -150℃ ~ +300℃, sowohl mit Kühl- als auch mit Heizfunktion.

6. Breite Palette von Anwendungen

Das TCU-Temperiergerät kann an verschiedene Prozessflüssigkeiten angepasst werden und ist in verschiedenen Industriebereichen weit verbreitet.

Die Umgebungstemperatur wird mit Hilfe von Temperatursensoren gemessen und geregelt, und ein intelligentes Kontrollsystem steuert automatisch die Arbeit der Kühl- und Heizgeräte, um die Innentemperatur stabil zu halten.

Wir sind Konstrukteur und Hersteller von Temperaturkontrollgeräten. Wir haben OEM-Produkte für die Luft- und Raumfahrt, die Automobilbranche, die Verteidigungsindustrie, die Energiewirtschaft, die chemische Industrie, die Medizintechnik und die Halbleiterindustrie entwickelt, die alle mit spezifischen Funktionen für die anspruchsvollen Bedürfnisse unserer Kunden ausgestattet sind.

E-Mail: lilia@lneya.com WhatsApp senden: +86 17851209193

Kühl- und Heizsysteme (Serie SUNDI)

Temperaturregelbereich: -120°C bis +350°C

Kühl- und Heizungsthermostate, die in verschiedenen Industriezweigen weit verbreitet sind.

| Temperaturbereich | Serie -10 ~ +150°C | Serie -25 ~ +200°C | Serie -25 ~ +300°C | Serie -45 ~ +250°C | Serie -45 ~ +300°C | Serie -60 ~ +250°C | Serie -60 ~ +300°C | Serie -70 ~ +250°C | Serie -80 ~ +250°C | Serie -90 ~ +250°C | Serie -100 ~ +100°C | ||

| Kühlleistung | 1,5 ~ 15kW | 1 ~ 200kW | 1 ~ 200kW | 0,45 ~ 200kW | 0,9 ~ 25kW | 0,25 ~ 60kW | 0,75 ~ 25kW | 0,4 ~ 15kW | 0,3 ~ 80kW | 0,2 ~ 80kW | 0,45 ~ 80kW | ||

| Hinweis: Jeder Temperaturbereich von -150℃ ~ +350℃ und jede Kühlleistung kann angepasst werden | |||||||||||||

Umwälzpumpen für Kühlung und Heizung

Temperaturregelbereich: -45°C bis +250°C

| Temperaturbereich | Serie -25°C ~ +200°C | Serie -45°C ~ +250°C | |||||||

| Kühlleistung | 1 ~ 15kW | 0,25 ~ 15kW | |||||||

| Hinweis: Jeder Temperaturbereich von -150℃ ~ +350℃ und jede Kühlleistung kann angepasst werden | |||||||||

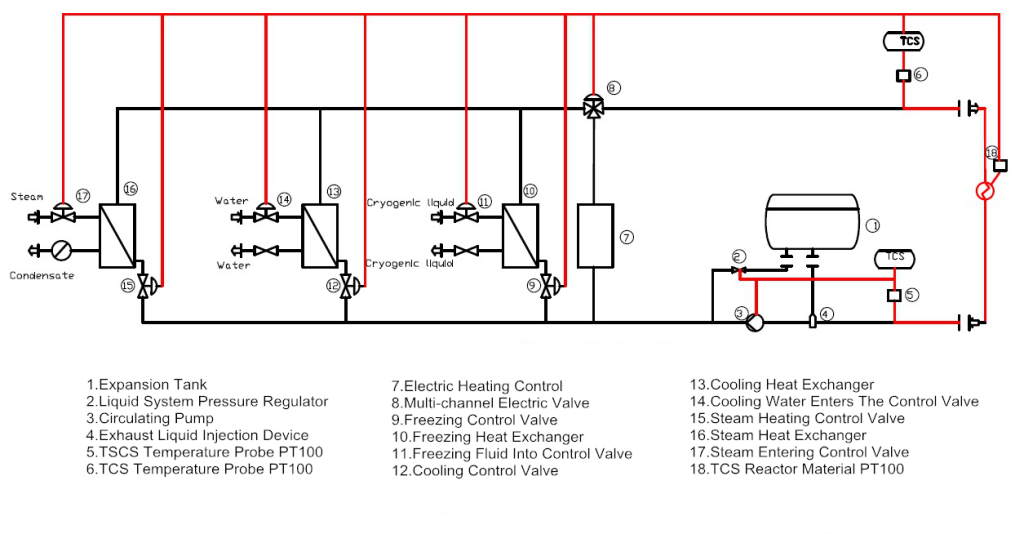

TCU Temperaturkontrollsystem

Temperaturregelbereich: -120°C bis +250°C

| Temperaturbereich | Serie -45°C ~ +250°C | -120°C ~ +250°C Reihe | Kundenspezifisches Temperaturkontrollsystem | RT+10°C ~ +135°C | |||||

| Heizleistung | 25 ~ 80kW | 25 ~ 80kW | Benutzerdefiniert | 25 ~ 300kW | |||||

| Hinweis: Jeder Temperaturbereich von -150℃ ~ +350℃ und jede Kühlleistung kann angepasst werden | |||||||||

Erzählen Sie uns von Ihrem Projekt, und wir entwerfen eine Kältemaschine für Sie

E-Mail: lilia@lneya.com WhatsApp: +86 17851209193

Bereich der industriellen Automatisierung

Im Bereich der industriellen Automatisierung werden TCU-Temperatursteuergeräte hauptsächlich zur Steuerung von Parametern wie Temperatur und Luftfeuchtigkeit in Produktionsstätten eingesetzt. Da die industrielle Produktionsumgebung komplex ist und hohe Anforderungen an Parameter wie Temperatur und Luftfeuchtigkeit stellt, muss das TCU-Temperatursteuerungsgerät eine hohe Präzision, hohe Stabilität und hohe Zuverlässigkeit aufweisen. Gleichzeitig wirken sich Temperaturschwankungen in industriellen Produktionsstätten auf die Produktqualität und die Produktionseffizienz aus, so dass das TCU-Temperatursteuerungsgerät auch die Eigenschaften einer schnellen Reaktion und präzisen Steuerung aufweisen muss.

Lebensmittelverarbeitende Industrie

In der lebensmittelverarbeitenden Industrie werden TCU-Temperiergeräte hauptsächlich zur Kontrolle von Parametern wie Temperatur und Feuchtigkeit in lebensmittelverarbeitenden Betrieben eingesetzt. Da in der Lebensmittelverarbeitung hohe Hygieneanforderungen gelten, muss das TCU-Temperaturregelgerät hohe Hygienestandards und eine hohe Zuverlässigkeit aufweisen. Gleichzeitig beeinträchtigen Temperaturschwankungen in Lebensmittelverarbeitungsbetrieben die Qualität und den Geschmack von Lebensmitteln, so dass das TCU-Temperatursteuergerät auch eine hohe Präzision und eine schnelle Reaktion aufweisen muss.

Labor

Im Labor wird das TCU-Temperatursteuergerät hauptsächlich zur Steuerung von Parametern wie Temperatur und Luftfeuchtigkeit im Labor verwendet. Da die experimentellen Umgebungen und die experimentellen Anforderungen im Labor unterschiedlich sind, muss das TCU-Temperatursteuergerät hochpräzise und anpassbar sein. Gleichzeitig wirken sich Temperaturschwankungen im Labor auf die Versuchsergebnisse aus, so dass das TCU-Temperatursteuerungsgerät auch eine hohe Stabilität und eine präzise Steuerung aufweisen muss.

Pharmazeutische Fertigungsindustrie

In der pharmazeutischen Industrie werden TCU-Temperiergeräte hauptsächlich zur Kontrolle von Parametern wie Temperatur und Luftfeuchtigkeit in pharmazeutischen Produktionsstätten eingesetzt. Da die pharmazeutische Produktionsumgebung hohe Hygieneanforderungen stellt, muss das TCU-Temperaturregelgerät hohe Hygienestandards und eine hohe Zuverlässigkeit aufweisen. Gleichzeitig wirken sich Temperaturschwankungen in pharmazeutischen Produktionsstätten auf die Qualität und Leistung von Medikamenten aus, so dass das TCU-Temperatursteuergerät auch eine hohe Präzision und schnelle Reaktion aufweisen muss.

Andere Bereiche

Neben den oben genannten Bereichen können TCU-Temperiergeräte auch in anderen Bereichen eingesetzt werden, in denen eine Temperaturregelung erforderlich ist, z. B. in der chemischen Industrie, der Energiewirtschaft, der Baustoffindustrie und anderen Branchen. In diesen Bereichen werden im Allgemeinen höhere Anforderungen an die Temperaturregelung gestellt, so dass das TCU-Temperaturregelgerät die Merkmale hohe Präzision, hohe Stabilität und hohe Zuverlässigkeit aufweisen muss.

Wir sind spezialisiert auf kundenspezifische Temperaturregelungssysteme. Wir haben unsere Flüssigkeitskühlsysteme für alle Arten von Halbleiteranlagen, FCEV-Wasserstofftankstellen und biopharmazeutische OEM-Prozesssteuerungssysteme entwickelt. LNEYA kann jede beliebige Form entwerfen, die um Ihre Anlage herum passt, Pumpenauswahlen, die alle Ihre Bedürfnisse erfüllen, luftgekühlt, wassergekühlt, mehrere Kühlkreisläufe. Spezielle Schnittstellenanforderungen, digital oder analog, Durchfluss- und Druckregelung der Wärmeübertragungsflüssigkeit am Pumpenausgang, Temperaturzyklen und -rampen sind möglich.

Bitte sprechen Sie uns an, wenn Sie ein speziell auf Ihre Bedürfnisse zugeschnittenes Temperiersystem benötigen. Wir beraten Sie gerne individuell und finden die richtige Lösung für Sie. Es ist auch möglich, Ihnen Referenzprojekte zu zeigen, die ähnliche Anforderungen haben und bereits realisiert worden sind.

Maßgeschneiderte Lösungen für Ihre Prozessbedürfnisse

Benutzerdefinierte Optionen

- Kundenspezifische Größen

Ob tragbare, kompakte, große oder kleine Kältemaschinen, wir können sie nach Ihren Anforderungen gestalten.

Ganz gleich, wie viele Tonnen Produkt Sie benötigen, wir können die beste Lösung finden.

- Benutzerdefinierte Temperaturbereiche

Wir können eine maßgeschneiderte Lösung für Temperaturen von -150℃ bis +350℃ entwickeln.

Kundenspezifische Temperaturbereiche für bestimmte Branchen.

- Individuelle Kühl-/Heizleistung

Wir bieten ein sehr breites Spektrum an Kühl-/Heizleistungen für verschiedene Branchen.

- Kundenspezifische Kälte-/Heizungsarten

Wir bieten Produkte verschiedener Kühl-/Heiztypen an, einschließlich, aber nicht beschränkt auf luftgekühlte, wassergekühlte und Verdunstungs-Kondensationskälteanlagen.

Unabhängig von der Art des Kältekompressors können wir ihn nach Ihren Anforderungen konstruieren.

- Kundenspezifisches Zubehör

Wir verwenden eine Vielzahl von international anerkannten Zubehörteilen, die alle auf Ihre Bedürfnisse zugeschnitten werden können, wie z. B. Kompressoren, Verdampfer, Wärmetauscher, Umwälzpumpen, Regler, Expansionsventile und Mantelmaterialien usw.

- Benutzerdefinierte Spannung

Passen Sie Spannung und Phase an Ihre Bedürfnisse an.

Optional 110V/60HZ, 220V/60HZ, 380V/50HZ, 220V/50HZ, 400V/50HZ, 460V/60HZ, 440V~480V/60HZ, etc.

- Andere Optionen

Bitte füllen Sie das untenstehende Formular aus und einer unserer Mitarbeiter wird sich in Kürze mit Ihnen in Verbindung setzen!

E-Mail: lilia@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

LNEYA

LNEYA

简体中文

简体中文