Cooling System in Data Center

Contact us today for the perfect temperature control solution

With the rapid development of Internet technology, the scale and number of data centers are also expanding. During the operation of the data center computer room, a stable and reliable refrigeration system is essential.

Classification of data center computer room refrigeration systems

Data center computer room refrigeration systems are mainly divided into two categories: air cooling and water cooling.

1. Air-cooled refrigeration system

Air-cooled refrigeration systems are the most common refrigeration method. They mainly use fans to extract hot air from the server room, and exhaust the heat to the outside through air conditioners or cooling towers.

The air-cooled refrigeration system is mainly composed of four parts: fan, condenser, evaporator and control system. The fan is responsible for extracting hot air from the server room; the condenser condenses the moisture in the hot air into liquid and releases a large amount of heat; the evaporator absorbs the moisture in the hot air from the condenser and takes away the heat at the same time; the control system Responsible for adjusting the fan speed to maintain a constant cooling effect.

The air-cooled refrigeration system has the advantages of simple equipment, easy maintenance, and relatively low cost. However, its energy efficiency ratio is relatively low and requires more electricity to maintain the cooling effect.

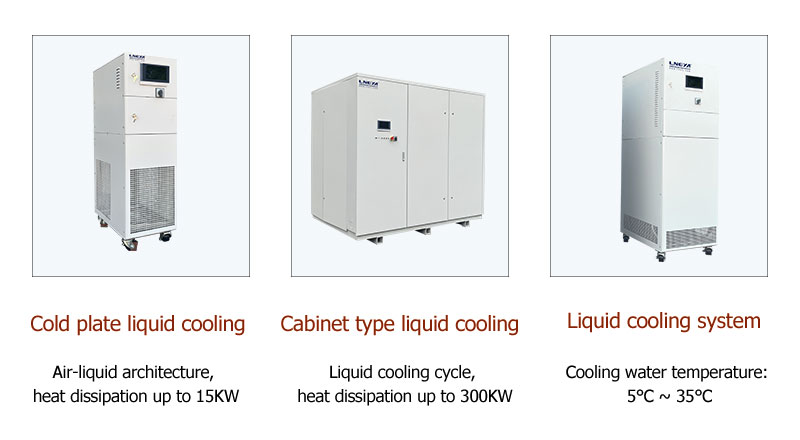

2. Water cooling refrigeration system

The water-cooled refrigeration system uses the heat of water to take away the heat of the server by directly contacting the server. Water cooling systems can be divided into two types: natural cooling and forced cooling. Natural cooling uses low-temperature water provided by the natural environment for cooling; forced cooling uses a refrigerator to cool the water below the ambient temperature, and then sends the cooled water to the server through a water pump for cooling. The advantage of the water cooling system is that it has higher energy efficiency under the same cooling effect, but the equipment is complex and the maintenance cost is high.

The future development trend of cooling system in data center

As energy prices rise and environmental protection requirements increase, the refrigeration system of data center computer rooms is developing in a more efficient and energy-saving direction. Future data center room cooling systems may be more inclined to use natural cooling or hybrid cooling to reduce dependence on power resources and reduce carbon emissions. At the same time, with the development of AI and big data technology, the cooling system of the data center computer room may also become more intelligent, able to automatically adjust the cooling effect and improve cooling efficiency. In addition, with the development of new materials, future data center room refrigeration systems may use more efficient heat dissipation materials to improve energy efficiency.

The cooling system of the data center computer room is an important factor in ensuring the stable operation of the data center. Whether air-cooled or water-cooled, each has its own unique advantages and disadvantages. In the future, we expect to see the emergence of more efficient, energy-saving, and smarter refrigeration systems to meet the growing cooling needs of data centers.

| Model | ZLFQ-15 | ZLFQ-25 | ZLFQ-50 | ZLFQ-75 | ZLFQ-100 | ZLFQ-150 |

| Temp range | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ |

| Cooling water | 5℃~30℃ Adopt Siemens/Honeywell regulating valve to control cooling water flow | |||||

| Temperature control accuracy | ±0.2℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ |

| flow control | 10~25L/min | 25~50L/min | 40~110L/min | 70~150L/min | 150~250L/min | 200~400L/min |

| The flow control is adjusted by frequency converter, the accuracy is ±0.3L/min | ||||||

| Cooling capacity (MAX) | 15kW | 25kW | 50kW | 75kW | 100kW | 150kW |

| Storage volume | 15L | 30L | 60L | 100L | 150L | 200L |

| Brine | Water, silicone oil, fluorinated liquid, ethylene glycol aqueous solution, etc. | |||||

| Medium pipeline | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 |

| In and out interface size | G3/4 | G1 | G1 | DN32 | DN40 | DN50 |

| Cooling water interface | G3/4 | G1 | DN40 | DN50 | DN50 | DN65 |

| Cooling water flow 7~20℃ | 2.5m³/h | 4m³/h | 8m³/h | 13m³/h | 17m³/h | 25m³/h |

| 380V 50HZ | 1kW | 1.5kW | 3kW | 4kW | 5kW | 6kW |

| shell | Cold-rolled sheet spray RAL7035 | |||||

| Model | ZLFQ-200 | ZLFQ-250 | ZLFQ-300 | ZLFQ-400 | ZLFQ-500 |

| Temp range | +5℃~35℃ | ||||

| Temp accuracy | ±0.5℃ | ||||

| Flow control | 15~30m³/h | 20~35m³/h | 25~40m³/h | 30~60m³/h | 40~70m³/h |

| Cooling capacity(MAX) | 200kW | 250kW | 300kW | 400kW | 500kW |

| Storage volume | 250L | 300L | 600L | 1000L | 1200L |

| Medium | Water, silicone oil, fluorinated liquid, ethylene glycol aqueous solution, etc. | ||||

| Medium pipeline | SUS304 | ||||

| In and out interface size | DN65 | DN65 | DN65 | DN80 | DN80 |

| Cooling water interface | DN80 | DN80 | DN100 | DN100 | DN125 |

| Cooling water flow 7~20℃ | 34m³/h | 43m³/h | 51m³/h | 69m³/h | 86m³/h |

| Power supply 380V 50HZ | 7kW | 7kW | 8kW | 9kW | 13kW |

| shell | Cold-rolled sheet spray RAL7035 | ||||

We provide complete temperature control system design and manufacturing. From standard models to complete customized products up to 1000 tons. We specialize in customer service and are dedicated to helping each customer have the optimal temperature control system for their specific need.

We provide non-standard customized solutions.

Email: info@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

LNEYA

LNEYA

简体中文

简体中文