CHILLERS

Professional Customized Chiller Equipment Manufacturer

A leading global manufacturer with 20+ year experience in research, development & production of water chillers – from mini chillers to large screw chillers with tons of cooling capacity, to keep cool for various industrial processing. We have designed OEM chillers for aerospace, automotive, defense, energy, chemical, industrial, medical, and semiconductor application, all delivered with capabilities specific to the demanding needs of our customers.

We have designed OEM chillers for aerospace, automotive, defense, energy, chemical, industrial, medical, and semiconductor application, all delivered with capabilities specific to the demanding needs of our customers. We provide non-standard customized water chiller solutions.

We have agents in many countries around the world, such as: United States, Russia, Australia, Netherlands, Sweden, Israel, Czech Republic, Malaysia, Singapore, Indonesia, Thailand, South Korea, India, etc. You can contact us or contact your local agent directly.

Any temperature range from -150℃ … +350℃ and any cooling capacity can be customized

1.Low Temperature/Cryogenic Chillers

- Temperature range: -150℃ ~ -5℃

- International brand compressor, high cooling efficiency

- Secondary subcooling technology, fast cooling speed

Six product series

| Model | LC series | LJ series | LN series | LD series | CDLJ series | SLJ series | |||

| Temperature range | -25 ~ -5 °C | -45 ~ -10 °C | -60 ~ -10 °C | -80 ~ -30 °C | -110 ~ -50 °C | -150 ~ -110 °C | |||

| Cooling capacity | 12 … 360 kW | 6 … 180 kW | 6 … 180 kW | 4 … 180 kW | 2 … 120 kW | 2.5 … 11 kW | |||

| Temperature stability | ±0.5 ℃ | ±0.5 ℃ | ±0.5 ℃ | ±0.5 ℃ | ±0.5 ℃ | ±0.5 ℃ | |||

| Pump flow pressure | 6.6 … 25 m³/h | 6.6 … 25 m³/h | 6.6 … 25 m³/h | 6.6 … 25 m³/h | 6.6 … 25 m³/h | 6.6 … 25 m³/h | |||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

2.Recirculating Chiller/Refrigerated Circulator

- Temperature range: -120℃ ~ +30℃

- International brand compressor, cascade refrigeration technology

- Use ethylene glycol or a mixture of ethylene glycol and water

Five product series

| Model | LX series | LT-45 series | LT-60 series | LT-80 series | LT-120 series | ||||

| Temperature range | -25 ~ +30 °C | -45 ~ +30 °C | -60 ~ -20 °C | -80 ~ -20 °C | -120 ~ -70 °C | ||||

| Cooling capacity | 0.8 … 30 kW | 0.75 … 12 kW | 0.4 … 6 kW | 0.2k … 6 kW | 0.3 … 5 kW | ||||

| Temperature stability | ±0.5 ℃ | ±0.5 ℃ | ±0.5 ℃ | ±0.5 ℃ | ±0.5 ℃ | ||||

| Pump flow pressure | 20 … 250 L/min | 20 … 50 L/min | 20 … 50 L/min | 20 … 50 L/min | 20 … 35 L/min | ||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

3.Small Chillers / Mini Chillers

3.Small Chillers / Mini Chillers

- Temperature range: -18℃ ~ +35℃

- International brand compressor, stable performance

- Energy saving, high temperature control accuracy

Two product series

| Model | FL-800 | FL series | |||||||

| Temperature range | -18 ~ +30 °C | +5 ~ +35 °C | |||||||

| Cooling capacity | 0.35 ~ 0.9 kW | 1.8 … 50 kW | |||||||

| Temperature stability | ±0.5 ℃ | ±0.5 ℃ | |||||||

| Pump flow pressure | 25 … 250 L/min | 10 L/min | |||||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

4.Cooling and Heating Chillers

- Temperature range: -120℃ ~ +350℃

- High-precision, intelligent temperature control

- Fully closed system to extend the service life of thermal fluid

Eleven product series

| Model | SUNDI-1 series | SUNDI-2 series | SUNDI-23 series | SUNDI-4 series | SUNDI-43 series | SUNDI-6 series | SUNDI-63 series | SUNDI-7 series | SUNDI-8 series | SUNDI-9 series | SUNDI-10 series | ||

| Temperature range | -10 ~ +150 °C | -25 ~ +200 °C | -25 ~ +300 °C | -45 ~ +250 °C | -45 ~ +300 °C | -60 ~ +250 °C | -60 ~ +300 °C | -70 ~ +250 °C | -80 ~ +250 °C | -90 ~ +250 °C | -100 ~ +100 °C | ||

| Cooling capacity | 1.5 … 15 kW | 1 … 200 kW | 1 … 200 kW | 0.45 … 200 kW | 0.9 … 25 kW | 0.25 … 60 kW | 0.75 … 25 kW | 0.4 … 15 kW | 0.3 … 80 kW | 0.2 … 80 kW | 0.45 … 80 kW | ||

| Temperature stability | ±0.5 ℃ | ±0.5 ℃ | ±0.5 ℃ | ±0.5 ℃ | ±0.5 ℃ | ±0.5 ℃ | ±0.5 ℃ | ±0.5 ℃ | ±0.5 ℃ | ±0.5 ℃ | ±0.5 ℃ | ||

| Pump flow pressure | 20 … 75 L/min | 20 … 600 L/min | 20 … 600 L/min | 20 … 600 L/min | 35 … 150 L/min | 20 … 250 L/min | 35 … 150 L/min | 20 … 110 L/min | 20 … 400 L/min | 20 … 400 L/min | 35 … 400 L/min | ||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||||||

5.High Temperature Chillers

- Temperature range: -100℃ ~ +80℃

- International brand compressors and other accessories

- Fully sealed design to ensure the purity of the medium

Five product series

| Model | FLT series | FLT-2 series | FLT-4 series | FLT-8 series | FLT-10 series | ||||

| Temperature range | +5 ~ +40 °C | -25 ~ +40 °C | -45 ~ +40 °C | -80 ~ +80 °C | -100 ~ +80 °C | ||||

| Cooling capacity | 6 … 40 kW | 2 … 15 kW | 1 … 8 kW | 0.6 … 3 kW | 1.5 … 3 kW | ||||

| Temperature stability | ±0.1 ℃ | ±0.1 ℃ | ±0.1 ℃ | ±0.1 ℃ | ±0.1 ℃ | ||||

| Pump flow pressure | 10 … 75 L/min | 10 … 75 L/min | 10 … 75 L/min | 7 … 45 L/min | 7 … 45 L/min | ||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

Customer application cases

|  |  |  |  | |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

We offer a variety of chiller types

We provide complete chillers design and manufacturing. From standard models to complete customized products.

We specialized in customer service and are dedicated to helping each customer have the optimal temperature control system for their specific need.

Didn’t find the right chiller? Or don’t know how to choose a chiller?

Contact us now to get detailed chiller details and prices

Email: lilia@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

Our chillers can be used for any industry

Including but not limited to the following industries

(A – Z)

| Aerospace | Anodizing & Plating | Automotive | Battery |

| Biotechnology | Brewery | Cannabis Extraction & Distillation | Casting Industry |

| Chemical | Commercial Buildings and Homes | Converting Industry | Cosmetics Workshops |

| Dairy Milk Processing | Data Center | Die Casting | Electric Car Battery |

| Energy Storage | Food & Beverage | Hazardous Processing | Heat Treating |

| Hospitals | Hydraulic Press | Industrial Manufacturing | Injection Molding |

| Integrated circuits test | Laboratory | Laser Cutting | Marine Solutions |

| Medical | Metal Finishing | Mining | Misting Equipment |

| Optical Coating | Paint Production Workshops | Pharmaceutical | Plastics Processing |

| Oil and Gas | Power Generation | Printing | Reactors |

| Renewable Natural Gas | Rotary Evaporator | Semiconductor Manufacturing | Textile and Yarn Industry |

| Thermal Spray | Thermal Vacuum Test | Waste Water Treatment | Welding Machines |

Customized Solutions for your Process Needs

CUSTOM OPTIONS

- CUSTOM CHILLER SIZES

Whether it is portable, compact, large and small chillers, we can custom design them according to your requirements.

No matter how many tons of chiller you need, we can create the best solution.

- CUSTOM TEMPERATURE RANGES

We can create a custom solution for temperatures from -150℃ to +350℃.

Custom temperature ranges for specific industries.

- CUSTOM COOLING CAPACITY

We offer a very wide range of cooling capacities for various industries.

- CUSTOM CHILLER TYPES

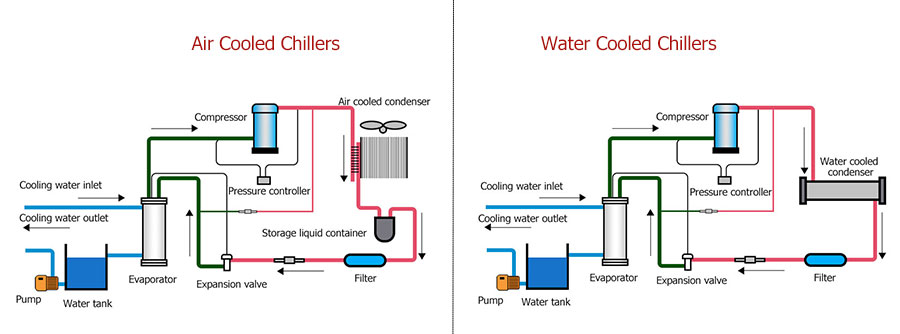

We provide chillers of various refrigeration types, including but not limited to air-cooled, water-cooled and evaporative-condensing chillers.

Regardless of the type of refrigeration compressor, we can design it according to your requirements.

- CUSTOM CHILLER ACCESSORIES

We use a variety of internationally renowned accessories, all of which can be customized for your needs, such as compressors, evaporators, heat exchangers, circulation pumps, controllers, expansion valves and shell materials, etc.

- CUSTOM CHILLER VOLTAGE

Customize chiller voltage and phase according to your needs.

Optional 110V/60HZ, 220V/60HZ, 380V/50HZ, 220V/50HZ, 400V/50HZ, 460V/60HZ, 440V~480V/60HZ, etc.

- OTHER CUSTOMIZED SOLUTIONS

Our Advantages

We specializes in custom temperature control systems. We have our liquid chiller system designs in everything from Semiconductor process equipment, FCEV Hydrogen Refeuling Stations and Bio-Pharmaceutical OEM process control systems. LNEYA can design any shape to fit around your equipment, pump selections to meet all your needs, air-cooled, water-cooled, multiple cooling loops. Special interface requirements, digital or analog, pump output heat transfer fluid flow and pressure control, temperature cycling and ramping all available.

Please contact us if you require a temperature control system specifically tailored to your needs. We will be happy to advise you individually and find the right solution for you. It is also possible to show you reference projects that have similar requirements and have already been realized.

Contact Us For Custom Solutions

Contact Us for further assistance with all standard and custom chiller needs

Dear Sir/Madam, please fill out the form below and one of our team members will be in touch shortly!

Email: lilia@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

LNEYA

LNEYA

简体中文

简体中文