Chillers for Automotive Industry

Our temperature control equipment has a wide range of applications in the automotive industry. Typical areas of application are environmental simulation, material testing and temperature-dependent stress and load testing of materials, gearboxes, bearings and engine parts, as well as research, testing and quality control of batteries, rechargeable batteries and electronic components.

Nowdays, our company has developed several new types of equipment for new energy batteries, motors, electronic controls, energy storage and charging piles and other fields.

Applications of Automotive Cooling

- Battery Testing

- Component Tests for Power Modules

- Converter and Inverter Test

- Environmental simulation

- Fuel Oil Test

- Materials Testing

- Motor Test Benches

- Temperature Control of Air

- Test Benchs

Tell us about your project, and we’ll design a chiller for you

We specializes in custom temperature control systems. We have our liquid chiller system designs in everything from Semiconductor process equipment, FCEV Hydrogen Refeuling Stations and Bio-Pharmaceutical OEM process control systems. LNEYA can design any shape to fit around your equipment, pump selections to meet all your needs, air-cooled, water-cooled, multiple cooling loops. Special interface requirements, digital or analog, pump output heat transfer fluid flow and pressure control, temperature cycling and ramping all available.

Please contact us if you require a temperature control system specifically tailored to your needs. We will be happy to advise you individually and find the right solution for you. It is also possible to show you reference projects that have similar requirements and have already been realized.

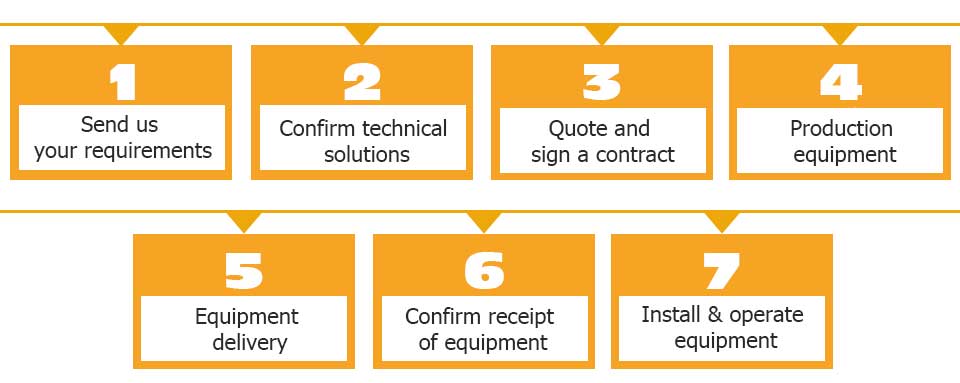

Order placement and manufacturing process

Chillers For Automotive Industry

We are a designer and manufacturer of temperature control equipment. We have designed OEM products for aerospace, automotive, defense, energy, chemical, industrial, medical, and semiconductor application, all delivered with capabilities specific to the demanding needs of our customers.

Email Us: info@lneya.com Send WhatsApp: +86 17851209193

Heat/Cool Temperature & Flow Control Systems

Heat/Cool Temperature & Flow Control Systems

Temperature simulation for vehicle quality test: battery life test, fuel injector/motor test bench, airbag test, component test bench, etc.

| Temperature range | -25°C ~ +100°C | -40°C ~ +100°C | 0°C ~ +100°C | -40°C ~ +135°C | |||||

| Cooling Capacity | 2.8 ~ 38kW | 1.2 ~ 60kW | 1.8 ~ 60kW | 4 ~ 60kW | |||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

Temperature / Pressure / Flow can be independently controlled.

1&2: one machine for two groups control.

| Temperature range | -40 ~ +100℃ 1&2 | 0 ~ +100℃ 1&2 | |||||||

| Cooling Capacity | 1.8kW*2 ~ 60kW*2 | 1.8kW*2 ~ 60kW*2 | |||||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

Temperature remains constant, pressure / flow can be independently controlled.

1&3: one machine for three groups control.

1&6: one machine for six groups control.

| Temperature range | -40 ~ +100℃ 1&2 | -40 ~ +100℃ 1&3 | -40 ~ +100℃ 1&6 | -20 ~ +100℃ 1&6 | 0 ~ +100℃ 1&2 | 0 ~ +100℃ 1&3 | 0 ~ +100℃ 1&6 | ||

| Cooling Capacity | 2.5 ~ 60kW | 4 ~ 60kW | 10 ~ 60kW | 10 ~ 60kW | 7 ~ 60kW | 11 ~ 60kW | 18 ~ 60kW | ||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

Oil Chillers

Temperature simulation for vehicle quality test: battery life test, fuel injector/motor test bench, airbag test, component test bench, etc.

| Temperature range | 0℃ ~ +160℃ | +5℃ ~ +135℃ | |||||||

| Cooling Capacity | 11 ~ 60kW | 15 ~ 38kW | |||||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

Cooling & Heating Systems For Electronic Pump

| Temperature range | -40°C ~ +135°C | ||||||||

| Cooling Capacity | up to 60kW | ||||||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

High Low Temperatuer Battery Test Chamber

| Temperature range | -40℃ ~ +100℃ | -40℃ ~ +100℃ | |||||||

| Cooling Capacity | 1.8 ~ 7.5kW | 4 ~ 15kW | |||||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

Automotive Direct Cooling Or Heating Systems

| Types | Direct Cooling | Direct Cooling & Heating | |||||||

| Cooling Capacity | 5 ~ 10kW | 5 ~ 10kW | |||||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

Email: info@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

Custom Solutions for your Process Needs

CUSTOM OPTIONS

- CUSTOM CHILLER SIZES

Whether it is portable, compact, large and small chillers, we can custom design them according to your requirements.

No matter how many tons of chiller you need, we can create the best solution.

- CUSTOM TEMPERATURE RANGES

We can create a custom solution for temperatures from -150℃ to +350℃.

Custom temperature ranges for specific industries.

- CUSTOM COOLING CAPACITY

We offer a very wide range of cooling capacities for various industries.

- CUSTOM CHILLER TYPES

We provide chillers of various refrigeration types, including but not limited to air-cooled, water-cooled and evaporative-condensing chillers.

Regardless of the type of refrigeration compressor, we can design it according to your requirements.

- CUSTOM CHILLER ACCESSORIES

We use a variety of internationally renowned accessories, all of which can be customized for your needs, such as compressors, evaporators, heat exchangers, circulation pumps, controllers, expansion valves and shell materials, etc.

- CUSTOM CHILLER VOLTAGE

Customize chiller voltage and phase according to your needs.

Optional 110V/60HZ, 220V/60HZ, 380V/50HZ, 220V/50HZ, 400V/50HZ, 460V/60HZ, 440V~480V/60HZ, etc.

- OTHER CUSTOMIZED SOLUTIONS

OUR ADVANTAGES

We offer:

Experience you can count on—

We’ve been designing and building custom products for more than 20 years. From medical chillers to energy storage chillers and everything in between, we’ve built products for virtually every industry and every application.

Same day quotes—

Get a quote for your project today! We often provide custom quotes in as little as 30 minutes.

24/7 customer service—

We are always here for you. Whether you have a question or need a quote, there’s always somebody here to communicate with you 24/7.

Durable, reliable equipment—

Our products are built with premium-grade materials, and we offer competitive warranties on all custom products.

Email: info@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

Advantages of Automotive Test Chillers

- The temperature of the antifreeze ranges from -40°℃~100℃

- Very steep temperature gradient

- Outlet temperature limit

- Visualization, data storage and reporting analysis

- The temperature control equipment can be flexibly connected with other test platforms

Equipped with a strong circulation pump, while ensuring the delivery of high viscosity liquid.

Using proportional control valve to control the flow output, the total range of precision control 5%~100% regulation

The use of closed circulation system, so as to avoid the antifreeze and the opportunity of contact with the outside air, to ensure that no moisture condensation.The expansion tank with nitrogen protection, the thermal liquid temperature range will be widened, because its boiling point has been increased. In addition, the oxidation produced by the contact between the thermal liquid and the oxygen in the environment is also avoided, thus extending the service life of the thermal liquid.

Accurate temperature control is particularly important for repeatability and accuracy of test results. The system is controlled by Siemens PLC. The electrical control section basically does not need human intervention to complete all the control.Because of this high level of automation , tolerance testing requires very little human effort. Industrial process thermostats can operate reliably at ambient temperatures ranging from 5 to 40 degrees – in hot summers, they can be run with cooling water up to 32 degrees.

Provides high operational security.The newly added security measures ensure the continuous unattended operation. A relevant running state data is continuously monitored and visualized on the touch screen.

The big color screen of Siemens 7″ provides clear and comprehensive important data information, including important information such as data, drawing lines and notes.

The touch interface optimizes the usability of the device.Multilevel users can be protected by password.The designated operator has limited permissions and can only accept Settings. This avoids accidental modification and misoperation of parameters. The operation is continuously monitored. Warnings and failures are displayed clearly and the system shuts down automatically if necessary.Faults can be traced, so testing doesn’t have to start all over again.At this point, existing records are invoked.The system has a variety of data and communication channels,can be adjusted according to the specific application. The temperature control unit can also be remotely controlled over a network or included in a control system.

Dear Sir/Madam, please fill out the form below and one of our team members will be in touch shortly!

Email: info@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

LNEYA

LNEYA

简体中文

简体中文