Chillers for Environmental Testing Equipment

In the environmental laboratory, a chiller is needed to remotely cool the laboratory equipment to maintain the normal operation of the test equipment. We know that the environmental test equipment is mainly based on simulating the natural environment, testing the product, and using the artificial simulated environment to achieve the effect of the product after 3-5 years in a short period of time.

Under the premise that various industries have higher and higher requirements for product quality, the requirements for the carrying capacity, high and low temperature range, and temperature change accuracy of environmental test equipment are getting higher and higher, and the equipment needs to respond quickly. Taking the refrigeration system of the environmental test chamber as an example, frequent starting and stopping and uninterrupted operation will inevitably increase the loss and energy consumption of the experimental equipment, and generate a large amount of heat, thus affecting the results of the environmental test.

The chiller can be used in environmental test equipment to provide independent and centralized cooling and cooling solutions for several or more than a dozen pieces of equipment to ensure the normal operation of the equipment.

In the cooling project of the other ring equipment, the remote control method is adopted, and the chiller can be flexibly customized according to the actual needs of users. The project is equipped with a remote control line of 12 meters and a power line of 22 meters. After on-site debugging, the chiller has completed the initial debugging and is running well.

In addition, for the installation requirements of the chiller, it is necessary to remind friends:

Before installing the chiller, the foundation should be flat and the surrounding area should be open to avoid corrosion, pollution, sunlight, and facilitate regular maintenance;

The water-cooled chiller should select the equipped cooling tower according to the cooling capacity of the chiller, and install it according to the size requirements. Do not reduce the size of the cooling tower to cause high pressure overload;

The air-cooled chiller should be installed in a space more than one meter away from the cavity wall, leaving enough space for the air inlet and outlet, which is conducive to equipment maintenance and avoids poor heat dissipation.

In addition, special attention should be paid to:

1. The power supply and load grounding parts should be constructed in accordance with relevant regulations.

2. The newly installed chiller chilled water pipe must be covered with insulation.

We are a professional manufacturer of temperature control equipment, supporting customized services, please consult us for details!

Temperature Control Range: -150°C to +50°C

Dynamic Temperature Control Systems

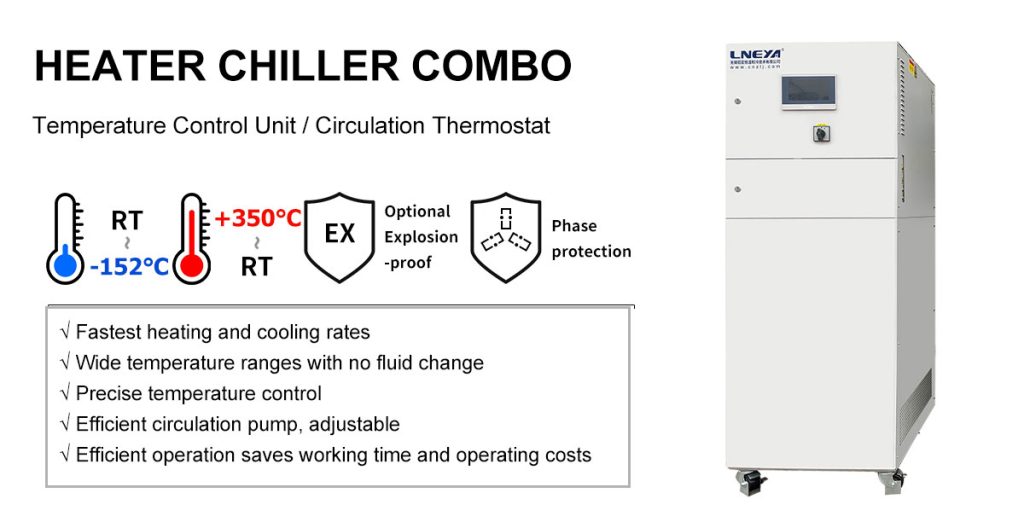

Temperature Control Range: -120°C to +350°C

Temperature Control Range: -40°C to +100°C

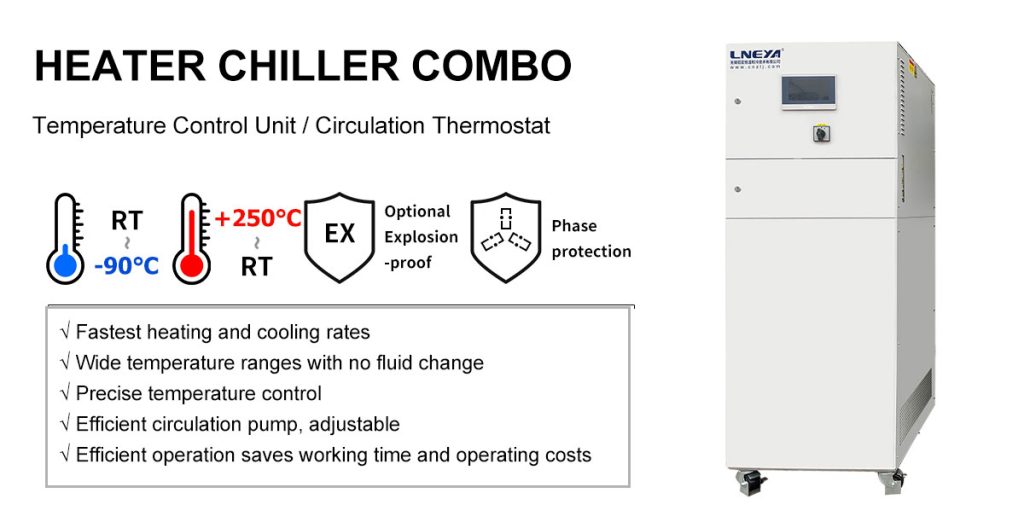

Temperature Control Range: -85°C to +250°C

Temperature Control Range: -150°C to -10°C

LNEYA

LNEYA

简体中文

简体中文