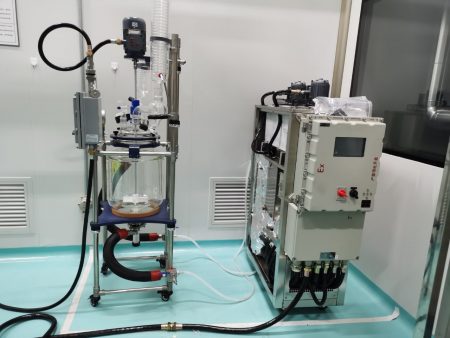

TCU Reactor Heating and Cooling Temperature Control Systems

The TCU reactor heating and cooling temperature control system can quickly heat up and cool down the material that needs to be cooled to achieve the required temperature, so that the equipment can achieve the expected effect, and it can also be used for heating and cooling of other equipment.

The TCU reactor heating and cooling temperature control system adopts international accessories, and the quality is guaranteed:

1. The heating and cooling temperature control system of the reactor adopts international brand accessories, compressor, expansion valve, condenser, circulation pump and other accessories are all international brands, and the copper pipe adopts anaerobic welding method.

2. RS485 communication function to realize automatic management and switching of heating and cooling power.

3.304 stainless steel integrated pipeline, reducing pipe resistance and rust.

4. Using imported components, the service life is long, and the electrical appliances are made of high-quality materials.

5. Stable operation, high efficiency, high precision, wide temperature range, easy and quick to use.

6. The control mode of the reactor heating and cooling temperature control system is controlled by imported microcomputer or PLC.

7. Reactor heating and cooling temperature control system has good alarm function, self-diagnosis, overload protection, high pressure switch overload electrical appliances, thermal protection device.

8. Rationally use heat energy, choose better process operating conditions, strengthen heat preservation measures, improve heat transfer efficiency, reduce heat loss to a minimum, and fully utilize waste heat or heat energy generated after reaction.

Features of TCU reactor heating and cooling temperature control system:

1. Fully enclosed heat transfer medium In a closed system, the expansion tank with heat transfer medium does not participate in the circulation process. Whether it is high temperature or low temperature, the temperature of the expansion tank is always kept at room temperature 60 ° C, which prolongs the service life of the heat transfer medium. The same medium is used, and continuous temperature control of -30°C~200°C, -40°C~200°C, and -80°C~200°C can be achieved without changing the medium and without pressurization.

2. The compressor is directly used for refrigeration at ultra-high temperature of 300°C, and the compressor can work for a long time during high-temperature exothermic reaction to control the temperature and take away excess heat.

3. Only the same medium can be used to control the temperature quickly, and the temperature control of the fluid system can be realized within the range of -120°C~300°C. The single compressor refrigeration technology can reach the lowest temperature of -150℃, and the volume is smaller.

4. Advanced dynamic temperature control technology. It ensures that the temperature accuracy of the liquid inlet and outlet and the material is only an error of ±0.3°C. When the temperature error is large, the control system will immediately issue instructions to control the exothermic and endothermic reactions to achieve rapid response temperature control.

5. The pipeline circulation system uses plate heat exchangers and pipeline heaters to increase the power density ratio, reduce the use of heat transfer medium, and improve the response speed of the system temperature control.

6. Heating protection control system. The equipment has multiple protections. When the temperature exceeds the temperature value set by the deviation protector in the system, the deviation protector will cut off the power of the solid state relay. Once the protector also has an error, the independent control system will play its role , With this triple protection, there will be no high temperature overshoot.

Features of TCU reactor heating and cooling temperature control system

Power-off protection: After power-off, the regulating valve is automatically closed, the heat source is cut off, the controller automatically resets, and various setting parameters and operating status parameters maintain the original settings before power-off.

Temperature difference protection inside and outside the kettle: The temperature difference between the jacket of the reaction kettle and the inside of the kettle can be set freely, and the system will automatically stop heating if the temperature difference exceeds the set value.

Overpressure protection: When the TCU system pressure exceeds the set upper limit (the setting value can be adjusted on the operation panel), the circulation pump will stop running, the steam regulating valve will be closed, and the cooling drain valve will be opened.

Energy saving: The programmable controller has adaptive PID control software, heating and cooling does not require cold and heat confrontation, and has the function of fast constant temperature calculation output.

Jacket/kettle control free switching: the whole set of equipment can be completely emptied; modular production, reasonable and compact structure.

Nous sommes un fabricant professionnel d'équipements de contrôle de la température et nous offrons des services personnalisés. nous consulter pour plus de détails !

LNEYA

LNEYA

简体中文

简体中文