HR-25N Recirculating Heater Chiller

Product parameter

- Power:4kW

- Heating power:2.5kW

- Flow:20L/min

- Pressure:2bar

- Temperature control accuracy:±0.5℃

All products support customized services

Phone: +86-18751545184

Search Search all

All products support customized services

Detailed Description

| Model | HR-25N | HR-35N | HR-50N | HR-70N | HR-100N | HR-150N | |

| Temperature Range | -25℃~200℃ | ||||||

| Controller | PID adaptive controller | ||||||

| Temperature Control | heat-conducting medium outlet temp.control | ||||||

| Temperature Feedback | Heat-conducting medium temperature feedback PT100(measure inlet temperature and outlet temperature) | ||||||

| Temp. Accuracy | ±0.5℃ | ||||||

| Heating Power | 2.5kW | 3.5kW | 5.5kW | 7kW | 10kW | 15kW | |

| Cooling Capacity | 200℃ | 2.5kW | 3.5kW | 5.5kW | 7kW | 10kW | 15kW |

| 100℃ | 2.5kW | 3.5kW | 5.5kW | 7kW | 10kW | 15kW | |

| 20℃ | 2.5kW | 3.5kW | 5.5kW | 7kW | 10kW | 15kW | |

| -5℃ | 2kW | 3kW | 4.5kW | 6.6kW | 8kW | 12kW | |

| -20℃ | 1kW | 1.8kW | 2.8kW | 3.8kW | 4.6kW | 7kW | |

| Circulation Pump Flow | Max20L/min | Max35L/min | Max35L/min | Max50L/min | Max60L/min | Max110L/min | |

| Circulation Pump Pressure | 1.2BAR | 1.2BAR | 1.2BAR | 1.2BAR | 1.5BAR | 1.5BAR | |

| Compressor | Tecumseh | Copeland/Danfoss | Copeland/Danfoss | Copeland/Danfoss | Copeland/Danfoss | Copeland/Danfoss | |

| Evaporator | Plate heat exchanger | ||||||

| Operation Panel | Display setting temperature and outlet and inlet temperature, 7-inch color touch screen | ||||||

| Data Record | U disk data export, Excel form, error record | ||||||

| Temperature Record | Record setting temperature, outlet and inlet temperature | ||||||

| Safety Protection | Self-diagnosis function; freezer overload protection; high pressure switch; overload relay; thermal protection device and other safety protection. | ||||||

| Closed Circulation System | The whole system is full closed circulation, there is no oil mist at high temperature and no water vapor at low temperature, pressure do not rise up when system is running. The system will supplement oil automatically at low temperature. | ||||||

| Refrigerant | R-404A/R507C | ||||||

| Connection Size | ZG1/2 | ZG3/4 | ZG3/4 | ZG3/4 | ZG1 | ZG1 | |

| Dimension(cm) | 40*70*130 | 45*70*160 | 45*70*160 | 55*70*175 | 65*85*185 | 70*85*185 | |

| Weight | 150kg | 165kg | 235kg | 265kg | 290kg | 320kg | |

| Power | AC 220V 50HZ | AC 380V 50HZ | AC 380V 50HZ | AC 380V 50HZ | AC 380V 50HZ | AC 380V 50HZ | |

| 4kW | 5.6kW | 8kW | 11kW | 15.5kW | 22kW | ||

| Case Material | Cold-rolled sheet spraying (standard color 7035) | ||||||

| Optional | MODBUS RTU Protocl, RS 232 interface | ||||||

| Optional Power | 220V 60HZ three-phase,440V~480V 60HZ three phase | ||||||

Customized Solution For Your Needs

We are a designer and manufacturer of temperature control equipment. We have designed OEM products for aerospace, automotive, defense, energy, chemical, industrial, medical, and semiconductor application, all delivered with capabilities specific to the demanding needs of our customers.

Custom Options

Whether it is portable, compact, large and small chillers, we can custom design them according to your requirements.

No matter how many tons of product you need, we can create the best solution.

We can create a custom solution for temperatures from -150℃ to +350℃.

Custom temperature ranges for specific industries.

We offer a very wide range of cooling / heating capacities for various industries.

We provide products of various refrigeration / heating types, including but not limited to air-cooled, water-cooled and evaporative-condensing chillers.

Regardless of the type of refrigeration compressor, we can design it according to your requirements.

We use a variety of internationally renowned accessories, all of which can be customized for your needs, such as compressors, evaporators, heat exchangers, circulation pumps, controllers, expansion valves and shell materials, etc.

Customize voltage and phase according to your needs.

Optional 110V/60HZ, 220V/60HZ, 380V/50HZ, 220V/50HZ, 400V/50HZ, 460V/60HZ, 440V~480V/60HZ, etc.

Our Advantages

We specializes in custom temperature control systems. We have our liquid chiller system designs in everything from Semiconductor process equipment, FCEV Hydrogen Refeuling Stations and Bio-Pharmaceutical OEM process control systems. LNEYA can design any shape to fit around your equipment, pump selections to meet all your needs, air-cooled, water-cooled, multiple cooling loops. Special interface requirements, digital or analog, pump output heat transfer fluid flow and pressure control, temperature cycling and ramping all available.

Please contact us if you require a temperature control system specifically tailored to your needs. We will be happy to advise you individually and find the right solution for you. It is also possible to show you reference projects that have similar requirements and have already been realized.

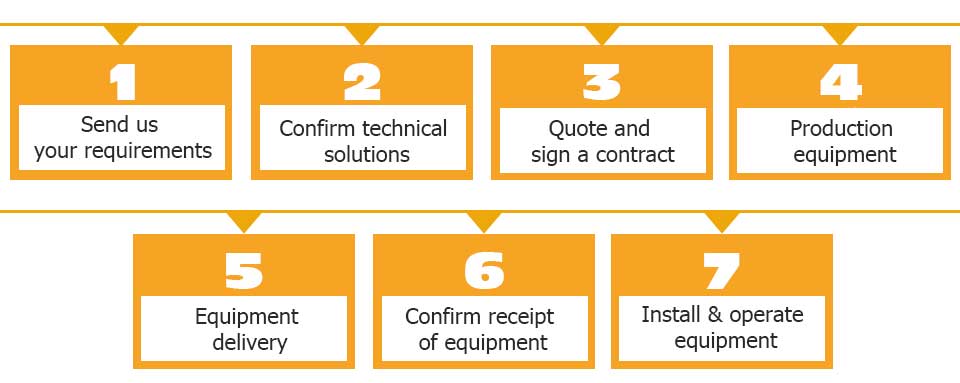

Order placement and manufacturing process

Contact Us For Custom Solutions

Contact Us for further assistance with all standard and custom chiller needs

Please fill out the form below and one of our team members will be in touch shortly!

Email: lilia@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

Guarantee that the goods are sold to be conform to the provisions of the contract and qualified new products by factory inspection, quality performance, technical indicators and configured are in accordance with manufactures and technical documents stipulated in the contract.

After the arrival of the goods, my company or my company agent is responsible for installation and debugging of equipment need on-site installation and debugging.

After installation and debugging, acceptance by the customer to confirm the goods to be conform to the provisions of the contract and qualified new products, quality performance, technical indicators and configured are in accordance with manufactures and technical documents stipulated in the contract, and after the confirmation of a full set of technical documents, sign the installation acceptance report and confirm acceptance.

At the same time of installation and debugging of equipment, my company’s after-sales service engineer is responsible for technical training for user until user can be skilled of operation. In the process of using equipment by customer, customer can consult relevant technical issues to after-sales service personal of our company at any time, according to the situation, my company will arrange training on site or remote.

A full free one year warranty since the date of acceptance, during the warranty period, all repairs and spare parts are free of charge(instrukent malfunction caused bu human factors will be charged of cost price of spare parts); After the warranty period, we will be responsible for maintenance of equipment for lifetime, according to the actual maintenance fees, appropriate fee will be charged.

(PS:There will have extra charge if the customer need on-site service. And customers need to describe the issue first and then send some failed pics or videos in advance, then Lneya judge if it is possible to go for after-Sales on site. )