Air Cooled Water Chillers – Industrial Air Chillers

The working principle of air cooled water chiller:

During operation, the refrigerant absorbs the heat of the object to be cooled (such as cooling water) and vaporizes in the evaporator, and the compressor continuously extracts the generated gas from the evaporator and compresses it into high-temperature, high-pressure steam. After being sent to the condenser, it exchanges heat with the air, condenses into a liquid after releasing heat, enters the evaporator after being depressurized by the throttling mechanism, and vaporizes again to absorb the heat of the object to be cooled, and the cycle repeats like this.

Features of air cooled water chiller:

Compared with the water-cooled chiller, the air-cooled chiller uses a finned condenser, which directly uses the fan to force the air flow to take away the heat of the refrigerant, without other auxiliary equipment, and saves the cooling tower, cooling water pump and cooling piping system. It has certain advantages in installation, especially for small chillers that do not require much cooling capacity, and it has great advantages in being easy to move.

Due to the difference in heat transfer temperature, under the same outdoor environmental conditions, the condensing temperature of the air-cooled chiller is higher than that of the water-cooled chiller, so the power consumption of the air-cooled chiller will be higher under the same cooling capacity. higher. In terms of energy efficiency, the cooling capacity of water-cooled units is generally 300~500 Kcal/h higher than that of air-cooled units.

The air-cooled chiller avoids the problems of condenser scaling and water pipe blockage in areas with poor water quality, and saves water resources. However, the heat transfer efficiency of the finned condenser used is greatly affected by the accumulation of dust and dirt. It is necessary to install a dust filter grid in front of the heat dissipation finned tube, and it needs to be cleaned regularly.

Application field of air cooled water chiller

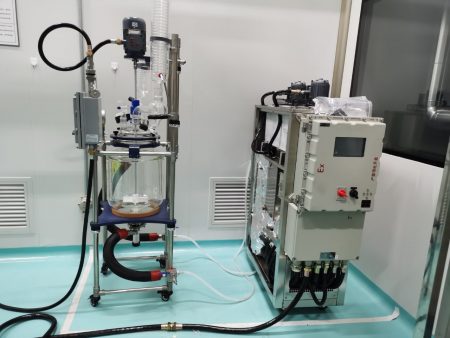

Pharmaceutical, chemical, food, grease, coating, electroplating, cold storage, plastic, chemical fiber, commercial concrete, laser, purification workshop, mechanical processing, agricultural planting, shopping malls and hotels, etc.

The difference between air cooled water chiller and water cooled water chiller

1. In terms of the size of the equipment, due to the difference in the working principle between the two, in terms of the size of the equipment, the air-cooled chiller is smaller than the water-cooled chiller, and the use and later maintenance It is also relatively simpler.

2. From the point of view of the efficiency and price of the machine, the water-cooled chiller is more powerful than the air-cooled chiller, and consumes less power. Although water-cooled equipment occupies a larger area, the price is much cheaper than air-cooled equipment.

3. The price of water-cooled equipment is relatively low, but a special machine room is required for use, while air-cooled chillers do not. Therefore, if there is no suitable site, it is more appropriate to choose an air-cooled chiller.

Temperature Control Range: -45°C ~ +250°C 7 Inch Color Touch Screen With 2pcs of LED Display Controller Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -25°C ~ +200°C 7 Inch Color Touch Screen With 2pcs of LED Display Controller Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -40°C ~ +200 °C Temperature Control Accuracy: ±0.5 °C 7-Inch,10 Inch color FTF Touch Screen Display Note: Both Air Coo...

Temperature Control Range: -10℃ ~ +150℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -25℃ ~ +200℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -25℃ ~ +300℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -45℃ ~ +250℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -45℃ ~ +300℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -60℃ ~ +250℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -60℃ ~ +300℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -70℃ ~ +250℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -80℃ ~ +250℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -90℃ ~ +250℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled Ar...

Temperature Control Range: -100℃ ~ +100℃ (optional: -150℃ ~ +350℃) Temperature Control Accuracy: ±0.5 °C Note: Both Air Cooled And Water Cooled A...

Temperature Control Range: -25°C ~ +200°C One Machine for Two Reactors Temperature Control Accuracy: ±0.5 °C 7-Inch,10 Inch color FTF Touch Screen...

Temperature Control Range: -40°C ~ +200°C One Machine for Two Reactors Temperature Control Accuracy: ±0.5 °C 7-Inch,10 Inch color FTF Touch Screen...

Temperature Control Range: -25°C ~ -5°C (optional: -150°C ~ -5°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Semi-Closed (Bipolar)...

Temperature Control Range: -45°C ~ -10°C (optional: -150°C ~ -5°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Semi-Closed (Bipolar...

Temperature Control Range: -18°C ~ +30°C Microcomputer Temperature Controller High Performance Circulating Pump Note: Both Air Cooled And Water C...

Temperature Control Range: +5°C ~ +35°C Microcomputer Temperature Controller High Performance Circulating Pump Note: Both Air Cooled And Water Co...

Temperature Control Range: -60°C ~ -10°C (optional: -150°C ~ -5°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Semi-Closed (Bipolar...

Temperature Control Range: -80°C ~ -30°C (optional: -150°C ~ -5°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Semi-Closed (Bipolar...

Temperature Control Range: -110°C ~ -50°C (optional: -150°C ~ -5°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Semi-Closed (Bipola...

Temperature Control Range: -150°C ~ -110°C Siemens PLC Controller, Danfoss Electronic Expansion Valve Semi-Closed (Bipolar) Piston Compressor, Sem...

Temperature Control Range: -25°C ~ +30°C (optional: -120°C ~ +35°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Brand Compressor, C...

Temperature Control Range: -45°C ~ +30°C (optional: -120°C ~ +35°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Brand Compressor, C...

Temperature Control Range: -60°C ~ -20°C (optional: -120°C ~ +30°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Brand Compressor, C...

Temperature Control Range: -80°C ~ -20°C (optional: -120°C ~ +30°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Brand Compressor, C...

Temperature Control Range: -120°C ~ -70°C (optional: -120°C ~ +30°C) Siemens PLC Controller, Danfoss Electronic Expansion Valve Brand Compressor, ...

Copyright information belongs to lneya-online.com, please contact email for details: lilia@lneya.com

Or scan the WhatsApp or WeChat QR code below to contact us.

WhatsAPP WeChat

LNEYA

LNEYA

简体中文

简体中文